Pressure-treated wood is everywhere in outdoor projects decks, fences, railings, stair stringers, posts, and more. It’s strong, rot-resistant, and built for harsh conditions. So it’s natural to ask: Should you paint pressure-treated wood? The honest answer is yes, you can but it’s not a “paint it this weekend” kind of project. The biggest factor is timing. If you paint pressure-treated lumber before it’s dry enough, you’re inviting peeling, bubbling, and a finish that fails long before it should.

This guide breaks down the real pros and cons, how long to wait, what happens if you paint too soon, and the best way to do it so your finish actually lasts. We’ll also compare painting vs staining, because in many outdoor situations stain is the smarter long-term choice.

Why pressure-treated wood is different (and why paint fails)

Pressure-treated lumber is infused with preservatives under pressure to protect it from rot, insects, and moisture damage. That treatment process usually leaves the wood wetter than standard lumber, and it can take a while to “season” and stabilise outdoors. While the chemicals themselves aren’t the main issue for paint, the moisture inside the wood is.

Paint forms a film on top of the surface. If the wood is still releasing moisture, that moisture tries to escape—pushing against the paint layer. The result is exactly what homeowners hate to see: blistering, bubbling, peeling, and flaking. Even if it looks fine for a few weeks, it can fail quickly once weather swings hit (heat, sun, rain, freezing nights, humidity).

That’s why painting pressure-treated wood is less about the brand of paint and more about dry time, prep, and using the right coating system.

Pros of painting pressure-treated wood

Added protection from sun and moisture

Pressure-treated wood is already protected against rot and insects, but paint can add another layer of protection—especially against UV exposure and surface moisture. Done correctly, paint helps reduce surface checking and slows down weathering, which can extend the “good-looking” life of the wood.

Strong, uniform look that hides the green tint

Fresh pressure-treated wood can have a greenish or brownish tone, and it often looks blotchy as it dries. Paint gives you opaque coverage, which makes everything look consistent and clean—especially on railings, trim, skirting, and visible boards.

Covers imperfections and repairs

If your deck or fence has patched areas, replaced boards, or mismatched lumber, paint is great for creating a uniform finish. It also hides small cosmetic flaws better than stain, which tends to highlight variations.

Cons of painting pressure-treated wood

The biggest risk: paint failure if you rush it

This is the number-one downside. Painting too soon traps moisture and leads to peeling or bubbling. If you’ve ever seen paint lifting in sheets on outdoor wood, there’s a good chance the wood wasn’t ready or the prep steps were skipped.

More prep and higher maintenance over time

Paint systems require more work: cleaning, sanding, priming, multiple coats, and careful dry times between steps. Long-term, painted surfaces can chip and peel and may require scraping and re-coating. Stain is often easier to refresh without heavy sanding.

Deck surfaces can get slippery if you use the wrong product

Standard exterior paint can become slick on deck floors when wet. If you’re coating a walking surface, you need a deck-rated coating designed for foot traffic, not a general exterior wall paint. For many homeowners, staining deck boards is the safer and lower-maintenance route.

Paint hides wood grain

If you like the natural character of wood, paint isn’t the right finish. It’s fully opaque and covers the grain completely.

How long should pressure-treated wood dry before painting?

If you want a durable finish, you need patience here. In most cases, pressure-treated lumber should dry for 3 to 6 months before painting. Sometimes it’s ready sooner, sometimes it takes longer—depending on the season, sun exposure, airflow, board thickness, and how the wood was stored.

Instead of guessing, use these simple checks:

The water-drop test (quick and reliable)

Sprinkle a few drops of water on the surface:

-

If the water beads up, the wood still has too much moisture or is too saturated to accept paint well.

-

If the water soaks in within a minute or two, you’re closer to “ready.”

The best method: a moisture meter

For homeowners who want certainty, a moisture meter removes the guesswork. Many pros aim for wood moisture content around 12–15% before painting. This isn’t a perfect universal number for every scenario, but it’s a practical range that aligns with strong adhesion and fewer failures.

What about “ready sooner” lumber?

Some pressure-treated wood is sold as kiln-dried after treatment. That type of material can be ready faster than standard wet PT lumber, but it still needs to pass the basic readiness tests.

What happens if you paint treated wood too soon?

If you paint before the wood is properly seasoned, the coating may look okay at first—then problems show up as the wood dries and the weather changes.

Common outcomes include:

-

Bubbling or blistering where moisture pushes against the paint film

-

Peeling at edges and joints, especially around fasteners and seams

-

Flaking in high-sun areas where heat speeds up moisture movement

-

Premature cracking as boards shrink and expand under a rigid finish

The worst part is the fix is rarely a quick touch-up. If the paint starts failing, you often have to scrape, sand, and re-prime before repainting. That’s why waiting for the right timing is usually cheaper—even if it feels slower.

Best primer for pressure-treated wood (and oil vs latex)

Primer is where a lot of paint jobs succeed or fail. Pressure-treated wood can be tricky because it’s outdoors, it moves, and it holds moisture longer than expected.

Latex primer is often the best starting point

In many exterior wood applications, a high-quality exterior latex bonding primer is a strong choice because it remains more flexible and breathes better than older, more rigid systems. Flexibility matters outdoors, especially on deck and fence parts that expand and contract.

When an oil-based primer might make sense

Oil primers can be useful for specific situations, like blocking stubborn stains or dealing with certain tannins or discoloration. But for pressure-treated wood, the bigger priority is compatibility with the paint and the wood’s moisture behavior. In many cases, exterior latex primer paired with exterior latex paint is the simplest and most reliable system—assuming the wood is properly dried.

If you’re using Sherwin-Williams products

The key isn’t the label on the can; it’s choosing an exterior-grade wood primer and a deck-rated product for any walking surfaces. If you want help matching a specific paint system to your deck or fence, it’s worth choosing the finish based on the surface type (railings vs floorboards vs posts) and sun exposure.

Best paint for treated wood

For most outdoor projects, choose a quality exterior latex/acrylic paint. It’s designed to flex with temperature swings, hold color better outdoors, and handle seasonal movement. Avoid rushing to oil-based topcoats unless you have a very specific reason and a compatible primer system.

If you’re coating a deck floor, make sure you’re using a deck-specific coating made for foot traffic. Deck floors live a harder life than railings and trim. People walk on them, drag furniture, shovel snow, and spill everything from grill grease to salt. A product meant for siding isn’t built for that.

How to paint pressure-treated wood the right way (step-by-step)

You don’t need a complicated process, but you do need a disciplined one. Here’s a straightforward approach that works for most outdoor PT wood projects.

1) Let the wood season

Give it time—typically 3–6 months—and confirm it passes the water-drop test (or use a moisture meter for accuracy). This step prevents most paint failures.

2) Clean thoroughly

Remove dirt, pollen, and mildew. If you wash the wood, give it enough time to dry again. Clean wood bonds better and helps the primer do its job.

3) Sand where needed

Light sanding helps smooth raised grain and improves adhesion. You don’t need to overdo it, but a quick scuff-sand can make a noticeable difference on older or rough boards.

4) Prime with an exterior wood primer

Primer helps the paint grip the surface and creates a more even base coat. Don’t skip it—especially on pressure-treated wood.

5) Paint in thin, even coats

Two coats is common. Thin coats cure better than heavy coats, and they’re less likely to crack. Respect dry times between coats—especially in cooler or humid weather.

6) Use the right product for the surface

Railings, trim, and vertical boards are easier to paint. Deck floors require deck-rated coatings to reduce slip risk and handle wear.

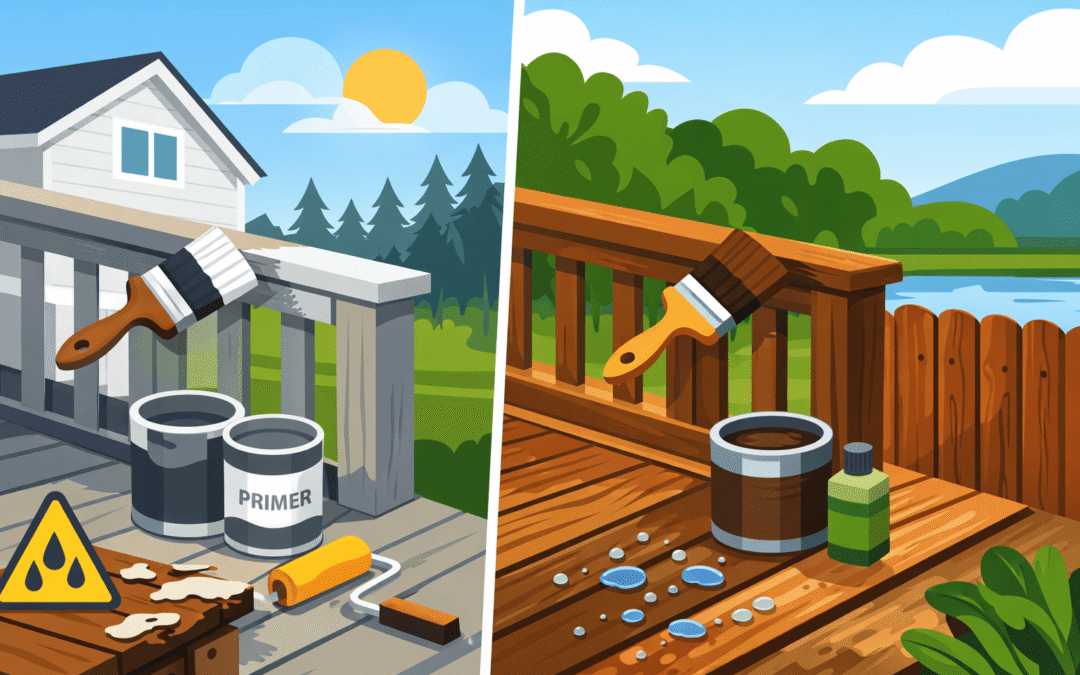

Is it better to stain or paint pressure-treated wood?

This is the question most homeowners should ask first, because the “best” finish depends on your priorities.

Stain is often the better long-term choice for decks

Stain penetrates the wood instead of forming a thick film on top. That usually means:

-

It’s more forgiving as the wood expands and contracts

-

It’s easier to refresh without scraping layers of peeling paint

-

It preserves more of the natural wood look (especially semi-transparent options)

For many deck floors, stain delivers a better balance of durability, traction, and maintenance.

Paint is better when you want a solid, uniform look

Paint wins when your goal is:

-

Full coverage color (no grain showing)

-

A clean “finished” look on railings, skirting, and trim

-

Hiding repairs, patched areas, and mismatched boards

A common best-of-both approach is stain the deck floor and paint the railings/trim, depending on the design and how the space is used.

Can you paint pressure-treated wood from Home Depot?

Yes—you can paint pressure-treated lumber from any supplier. The important part is understanding that much of the pressure-treated wood sold at big-box stores is still wet and fresh from treatment. That means it’s usually not ready for paint right away.

If you’re buying PT wood and planning to paint it, your best move is:

-

Let it season properly

-

Test readiness (water-drop test or moisture meter)

-

Prep and prime correctly

The store isn’t the issue—timing and prep are.

A quick note about Core Improve (and how we help)

At Core Improve, we’re a family-owned, fully insured team serving Chicago and the surrounding suburbs with deck building and deck replacement, deck repair, deck restoration, deck staining, fence building, fence repair, fence replacement, and fence staining. What makes our work easier for homeowners is that we don’t just build we also maintain and protect. If your deck is new and you’re waiting for the right moment to finish it, or your existing deck needs repairs before staining or painting, we can handle the full scope: inspection, board replacement, prep, and a finish system that matches how you actually use the space.

Final takeaway

You can paint pressure-treated wood and when done correctly, it can look fantastic and add protection. But success comes down to one thing: don’t rush the wood’s dry time. Let it season, test readiness, prep properly, prime, and choose the right coating for the surface. If you want a lower-maintenance finish especially for deck floors stain is often the smarter option.

FAQs: Painting pressure-treated wood

Is it better to stain or paint pressure-treated wood?

For many decks—especially deck floors—staining is often lower maintenance and more forgiving. Paint is best when you want a solid color and need to hide imperfections, but it requires more prep and can peel if conditions aren’t right.

What happens if you paint treated wood too soon?

Moisture trapped in the wood can cause bubbling, blistering, peeling, and early failure. You may end up scraping and repainting sooner than expected.

Best paint for treated wood?

A high-quality exterior latex/acrylic paint is usually the safest all-around choice. For deck floors, use a deck-rated coating designed for foot traffic.

How long should pressure-treated wood dry before painting?

Most pressure-treated lumber should season for about 3–6 months, but conditions vary. Use the water-drop test or a moisture meter to confirm it’s ready.

Best primer for pressure-treated wood?

A quality exterior primer designed for wood is typically recommended, and many projects do well with exterior latex primers when the wood is dry.

Can you paint pressure-treated wood from Home Depot?

Yes, but most PT lumber is still wet when purchased. The key is letting it season and testing readiness before priming and painting.

Oil or latex primer for pressure-treated wood?

Latex primers are commonly used for flexibility and exterior performance. Oil primers can be useful in certain stain-blocking situations, but compatibility and wood dryness matter most.

Painting pressure-treated wood with Sherwin-Williams: what should I use?

Choose an exterior wood primer and an exterior paint system suited to your surface type. For deck walking areas, select a deck-rated product made for foot traffic rather than standard exterior wall paint.